Unleash the Potential of CO₂ in Industrial Refrigeration

The Vilter transcritical and subcritical single-screw CO2 compressor platforms solve the industrial demands for more robust, reliable and simple CO2 alternatives. Based on high-pressure application experience in rugged, dirty and open-loop conditions in the renewable natural gas (RNG) industry, Vilter’s technological expertise is well-equipped to address today’s CO2 application requirements.

Expanding Capacity and Reliability with Vilter Co2 Compression

Rapid expansion leads a leading food supplier to upgrade its refrigeration infrastructure, ensuring that it could sustain increased production volumes while maintaining high reliability and energy efficiency.

Inside Story

See what makes the Vilter by Copeland single-screw compressor so unique.

Advantages of the Vilter CO₂ System

Simplifying Industrial Refrigeration

- CO2 provides a solution to dynamic and uncertain regulations

- Integrates compressors, controls and oil management components to streamline system design

- Delivers high tonnage capacities with fewer industrial compressors

- Operates with fewer system parts — such as pipes, elbows and valves — which reduces potential failure and leak points while making system troubleshooting easier

- Removes the need for superheat which reduces system complexities and increases efficiencies

- Utilizes industrial-grade welded pipe versus brazed copper to reduce leak potential

- Avoids ammonia safety concerns and complexities associated with potential leaks

Enhance Reliability

- Reduces maintenance costs and prolongs equipment lifespan

- Improves uptime with fewer production shutdowns and delays

- Delivers lower total cost of ownership (TCO)

Purpose-Built for Industrial Rigors

- Supports high tonnage capacities

- Engineered with industrial-grade technology and componentry

- Withstands high transcritical CO2 pressures

- Meets load demands without requiring superheat

Meet Sustainability Goals

- Uses natural refrigerant CO2 with a GWP of 1 to help reach your sustainability goals

- Offers high heat reclamation potential (i.e., water heating, etc.)

- Reduces system footprint, requiring less installation space and saving facility resources

- Includes access to Vilter Lifecycle Services support and CO2 expertise to help your company solve application challenges

Industrial CO₂ Compression Starts Now

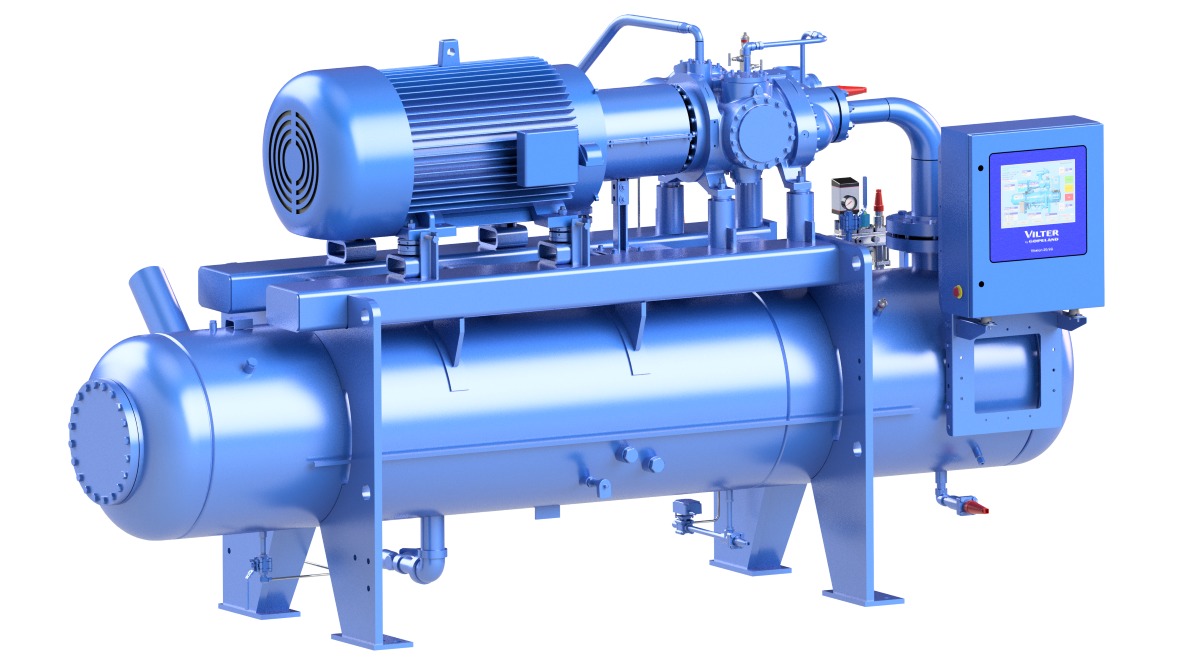

The Vilter transcritical CO2 single-screw compressor is purpose-built for industrial refrigeration. Individual and multiple compressor configurations can be leveraged to address a wide breadth of tonnage and temperature requirements.

One transcritical CO2 single-screw compressor can be applied in single-stage, higher-temperature applications, or in a CO2 two-stage configuration, which also utilizes the subcritical CO2 single-screw compressor for low-side loads.

Vilter offers solutions in single- and double-compressor configurations. A double-compressor configuration increases unit capacity while sharing common oil management and control systems to reduce costs and application footprint.

Subcritical CO₂ Industrial Compressor

Part of Vilter’s industrial refrigeration CO2 solutions, purpose-built for subcritical applications to deliver reliability, simplicity, and longer system life. This model meets new sustainability goals with Vilter’s proven single-screw technology.

Transcritical CO₂ Industrial Compressor

Building on our legacy of innovations, Vilter has engineered one of the industry’s first transcritical CO2 screw compressor — purpose-built for heavy-duty industrial requirements and rated for CO2 transcritical pressures.

Documents

| Name | Languages | File Type | Link |

|---|---|---|---|

| Unleash the Potential of CO2 in Industrial Refrigeration | English | Download |

| Name | Languages | File Type | Link |

|---|---|---|---|

| E360 Article – Natural Selection | English, Français | Download |

| Name | Languages | File Type | Link |

|---|---|---|---|

| Food company prioritizes performance | English | Download |