Advancing the next generation of low-carbon thermal systems

Precise temperature control is essential for consistent product quality, safe production and reliable throughput in nearly every industrial operation — from food and beverage to pharmaceuticals, chemicals, pulp/paper and manufacturing.

Today’s operators face mounting challenges: maintaining uptime in continuous processes, managing rising energy costs and transitioning to eco-friendly refrigerants. With decades of application expertise, Copeland’s Vilter and SPH solutions help customers modernize process heating and cooling systems to improve performance, reduce total cost of ownership and meet the evolving standards of a low-carbon future.

Engineered to decarbonize rigorous industrial processes

Across process industries, demand for technologies that deliver exceptional reliability, energy optimization and high performance with low-maintenance requirements continues to grow. Meanwhile, decarbonization policies and operator sustainability goals are accelerating the transition from fossil-fuel heating to integrated heat recovery strategies and the adoption of low-global warming potential (GWP) and natural refrigerant technologies.

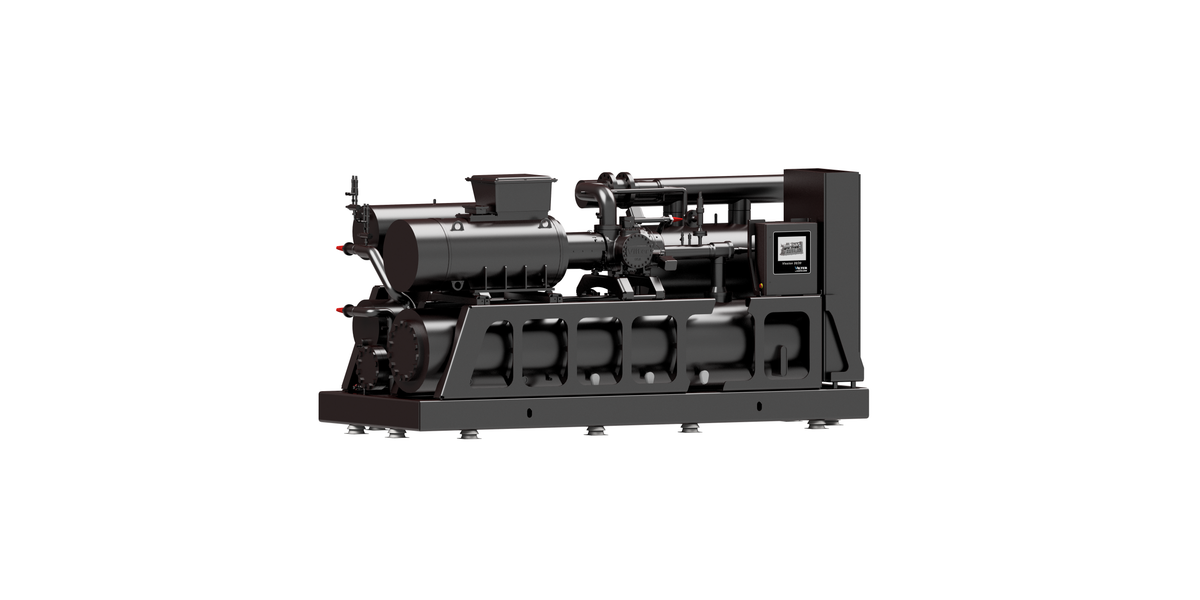

With the recent acquisition of SPH Sustainable Process Heat, Copeland has significantly expanded our industrial heating portfolio under the Vilter brand. From industrial heat pumps and process chillers to single screw and reciprocating compression technologies, we now offer an even broader range of solutions to help process industry operators maintain uptime in the most rigorous applications, minimize operating costs and cut carbon emissions. Our expanded capabilities enable us to support a wider range of refrigerants, optimize performance and efficiency and provide cost-effective ownership while reducing carbon emissions.

Turnkey support for process industries

Copeland offers comprehensive support and services to help operators maintain uptime and maximize the return on their equipment investments. Backed by decades of process industry expertise, purpose-built industrial technologies and a proven track record of reliability, Copeland provides solutions that address processing plants unique operational requirements.

Why choose Copeland?

With over a century of experience in industrial process heating and cooling innovations, our Vilter brand offers trusted solutions for food and beverage, pharmaceutical, chemical/petrochemical, pulp/paper and other manufacturing sectors. We understand the variability of these applications and help operators by developing configured-to-order and custom solutions that meet their unique operational requirements, achieve their decarbonization goals and ensure process uptime above all else.

What sets us apart:

- Integrated heat recovery for process industries

- Improved energy efficiency and consistent performance

- Reduced carbon emissions and operational costs

- Reliable, customizable solutions for industrial processing requirements

- Decades of trusted industrial process heating and cooling experience

- Comprehensive service and support

- Specialization in designing, manufacturing and servicing heat pumps for industrial steam applications with temperatures up to 180°C

Supporting the transition to energy-efficient, low-carbon processing

Copeland supports leading industrial processors in maintaining uptime and decarbonizing their operations with low-GWP, energy-efficient heat pump and compression technologies. Recent examples demonstrate our ability to develop custom solutions that meet a range of operational and decarbonization goals.