A2L-Qualified Refrigeration Solutions

Compressors, Condensing Units and Controls

Offering an ideal combination of lower-global warming potential (GWP), high performance and larger charge sizes than R-290, A2L refrigerants have the potential to fill a much-needed niche across a broad range of applications. The A2L “lower flammability” classification requires an increased focus on equipment and application safety. Copeland is developing the next generation of A2L compression technologies across its major product platforms, qualified for use with R-455A (146 GWP), R-454C (148 GWP) and R-454A (238 GWP). Our deep compression portfolio, leak detection sensors and supervisory control architectures are designed to maximize A2L application safety and refrigeration reliability.

Copeland currently has product samples available for their original equipment manufacturer (OEM) customers across its major Copeland scroll, semi-hermetic, hermetic reciprocating, and condensing unit platforms. Copeland plans to release all full-production A2L models across its major product lines by 2024. Contact us to learn more about our A2L-qualified refrigeration solutions.

A2L-Qualified Copeland Compressors

- YF SCROLL COMPRESSOR

- YS SCROLL COMPRESSOR

- YB SCROLL COMPRESSOR

- YSH/YFH SCROLL COMPRESSOR

- DISCUS COMPRESSOR

YF Scroll Compressor

Copeland YF scroll compressor models are designed for use in low- to medium-temperature A2L refrigeration applications such as walk-in freezers and reach-in display cases. These scroll compressors are qualified to use multiple A2L refrigerants while delivering the lower sound and vibration levels that are preferred in supermarket, restaurant, and convenience store operations.

- Available in 1 to 9 HP (3k to 22k BTU/hour at standard low-temperature rating conditions)

- Covers evaporating temperatures from -40 to 10 °F

- Qualified for multiple refrigerants, including: A2Ls refrigerants R-455A, R-454C and R-454A and A1 refrigerants R-404A, R-507. R-407A. R-407C, R-448A, R-449A, R-134a

- Digital modulating YFD models available

YS Scroll Compressor

Copeland YS scroll compressor models are designed for use in medium- to high-temperature A2L refrigeration applications such as walk-in coolers, reach-in display cases, soft serve and frozen carbonated beverage equipment. Smooth scroll mechanics provide higher reliability and lower sound and vibration while the hermetic design reduces the potential for refrigerant leaks. These factors make YS models well-suited for supermarket, restaurant and convenience store environments.

- Available in 1.25 to 4.5 HP (9k to 30k BTU/hour at standard medium-temperature rating conditions)

- Covers evaporating temperatures from -25 to 45 °F

- Qualified for multiple refrigerants, including: A2L refrigerants R-455A, R-454C and R-454A and A1 refrigerants R-404A, R-507, R-407A, R-407C, R-407F, R-448A, R-449A, and R-134a

YB Scroll Compressor

Copeland YB scroll compressor models are designed for use in medium- to high-temperature A2L refrigeration applications. A wide capacity range expands the application potential of these flexible scroll compressors — from small reach-in displays and large beverage coolers to walk-in coolers.

- Available in .75 to 9 HP (6k to 50k BTU/hour at standard medium-temperature rating conditions)

- Covers evaporating temperatures from -10°F to 45°F

- Qualified for multiple refrigerants, including: A2L refrigerants R-455A, R-454C and R-454A and A1 refrigerants R-404A, R-507. R-407A. R-407C, R-407F, R-448A, R-449A, R-134a

- Digital modulating YBD models available

YSH/YFH Scroll Compressor

Copeland YSVH horizontal scroll compressor models offer low-profile commercial refrigeration design advantages and legendary scroll reliability in medium- to high-temperature A2L such as walk-in, reach-in, coolers, soft serve and frozen carbonated beverage applications. Maximize merchandizing space, flexibility and safety while minimizing noise levels and vibration in refrigerated display cases.

- Available in 1.5 to 5 HP (2k to 24k BTU/hour at standard medium-temperature rating conditions)

- Covers evaporating temperatures from -25F to -45F

- Qualified for multiple refrigerants, including: R-455A, R-454C and R-454A

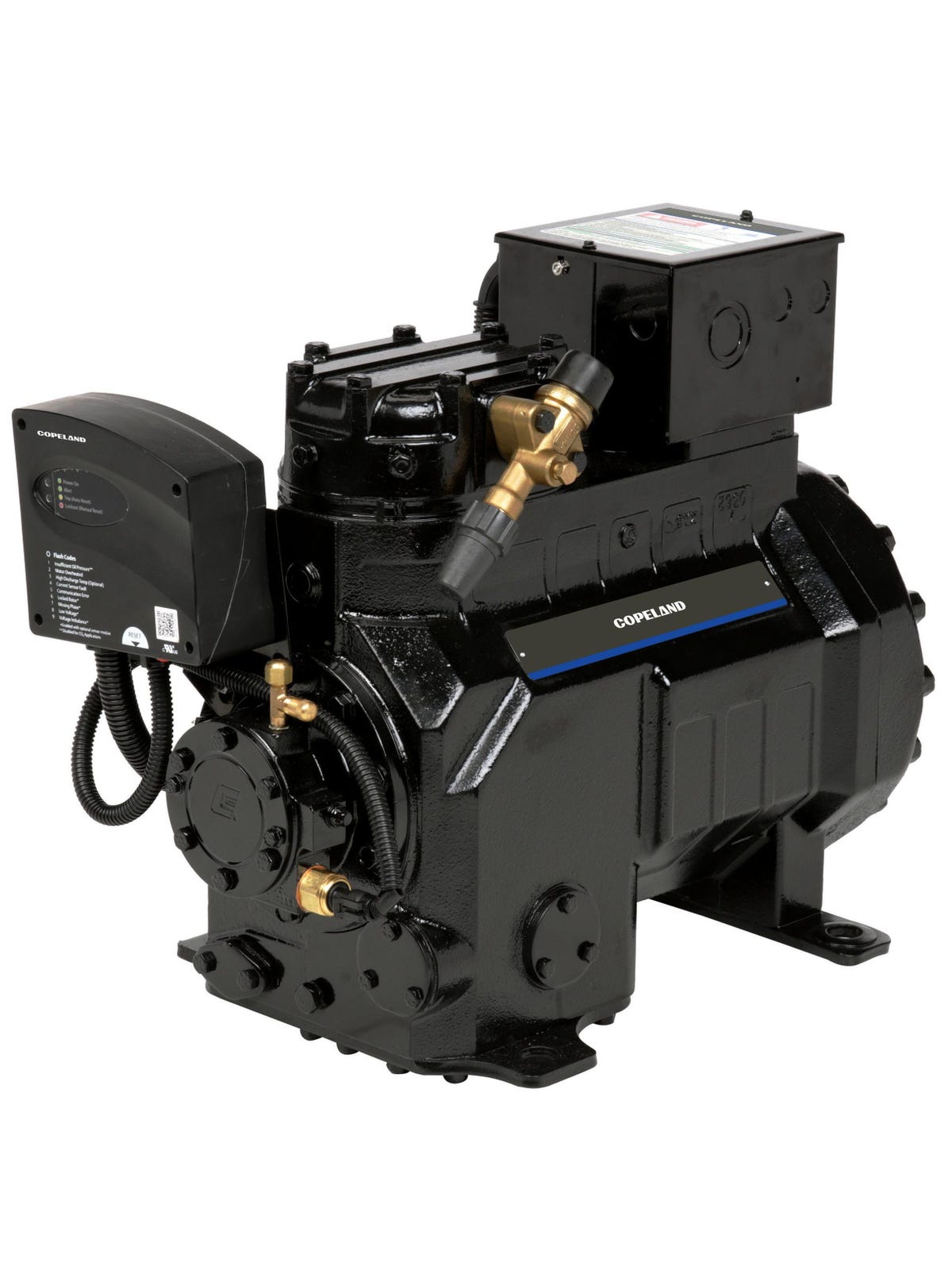

Discus Compressor

Copeland Discus semi-hermetic compressors have been the unquestioned leader in commercial refrigeration for over 30 years. Combining world class efficiency and reliability, Discus is the compressor of choice to meet your refrigeration needs. The unique Discus valve design provides improved efficiency at operating conditions where most semi-hermetic compressors run. Grueling life-testing and 30 years of field experience make Discus compressors the most reliable compressor in the industry.

- Available in 3 to 40 HP for medium-temperature and low-temperature applications

- Qualified for multiple refrigerants, including: A2L refrigerants R-455A, R-454C and R-454A and A1 refrigerants R-404A, R-507, R-407A, R-407C, R-407F, R-448A, and R-449A

A2L-Qualified Copeland Valves, Controls and System protectors

- PRODUCT COMPONENTS

A2L-Qualified Copeland Valves, Controls and System protectors

We offer UL-certified components for A2L refrigerants including solenoids, expansion valves, filter driers, oil controls and more, with capacity ranges for a wide variety of applications

A2L-Qualified Copeland™ Condensing Units

- F-LINE SCROLL CONDENSING UNIT

- X-LINE OUTDOOR CONDENSING UNIT

F-Line Scroll Condensing Unit

Designed for medium- and low-temperature, walk-in coolers, freezers and display cases commonly found in c-stores and restaurants and with diagnostic protection and electronic unit cooler, the F-Line is part of the industry’s broadest line of integral horsepower condensing units for refrigeration applications.

- Primary Applications: Walk-Ins (where AWEF approved), Reach-Ins, Display Cases, Air Dryers

- Horsepower Range: 3/4 - 13 HP

X-Line Outdoor Condensing Unit

Designed for medium- and low-temperature, walk-in coolers, freezers and display cases commonly found in c-stores and restaurants and with its best-in-class energy efficiencies, slim profile, ultra-low sound levels, superior diagnostics and built-in protection, the X-Line delivers reliable commercial refrigeration while solving many of today’s small-format retailer challenges.

- Primary Applications: Walk-Ins and Display Cases

- Horsepower Range: 3/4 - 6 HP

Advanced A2L System Management and Controls

- E3 SUPERVISORY CONTROL

- XM600 SERIES CASE CONTROLS

E3 Supervisory Control

Safely deploy emerging A2L refrigeration applications with the industry’s most advanced facility management and refrigeration control platform. The E3 is designed with A2L control logic to oversee system monitoring and safety management by integrating Copeland case controls, leak detection and sensing devices.

- Provides remote alarming in event of a refrigerant leak

- Leverages advanced data analytics to uncover insights and enable slow leak detection capabilities

- Supports condition-based maintenance (CBM) business models

- Enables deep visibility into key aspects of refrigeration performance to inform decision-making

XM600 Series Case Controls

A2L-qualified case controls deliver worry-free, case-level optimization and seamless integration with the E3 supervisory control. The XM600 Series case controls are designed to:

- Manage defrost and minimum defrost time

- Control pump-down before defrost

- Support multiple probe regulations

- Integrate with E3, E2 and Site Supervisor controllers

- Provide parameter maps with DI switching for stand-alone use

- Enable in-the-field firmware upgrades for enhanced serviceability

A2L Leak Detection

- MRLDS-450 GAS DETECTORS

- REFRIGERANT LEAK DETECTION SYSTEM

MRLDS-450 Gas Detectors

MRLDS-450 gas detectors leverage diffusion-based technology to help operators ensure system safety, optimize performance, and provide clear indications of A2L refrigerant leaks.

- Detection range: 0 to 30,000 and 0 to 50,000 parts per million (PPM)

- One- or two-sensor capabilities

- Point sensor provides 24/7 monitoring for safety compliance purposes

- Remote sensor capabilities support flexible placement

- Analog and digital interfaces enable ease of integration with control devices

- Onboard relays

- Status indicator and LED display provide quick status checks

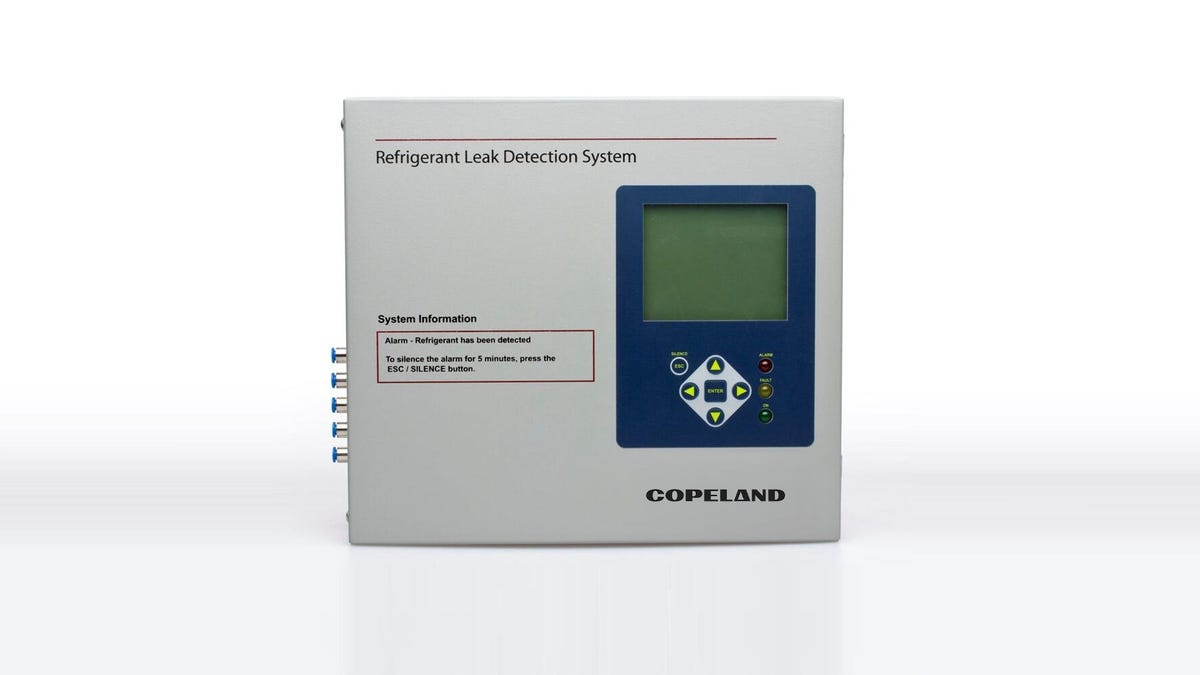

Refrigerant Leak Detection System

Refrigerant Leak Detection System (RLDS) delivers multi-zone coverage via aspirated system technology to detect A2L leaks early, minimize refrigerant loss, and maximize safety.

- Detection range: 0 to 10,000 PPM

- Includes an audible alarm, front panel indicators and built-in relays to trigger external alarm devices in the event of a fault for immediate response

- Continuously monitors up to 16 separate zones

Copeland Variable Frequency Drives

- EVM SERIES

EVM Series

EVM Series drives are ideal for A2L refrigeration applications, pairing seamlessly with Copeland compressors to deliver significant improvements in system performance and reliability, substantial reductions in energy consumption and a fast return on investment.

- Qualified for use in systems with flammable refrigerants as per the A2L and A3 refrigerant compliance requirements in UL 60334-2-89

- Covers 0.5 to 30 HP range

- Available in single- and three-phase input options

- Equipped with onboard Bluetooth™ capabilities for ease of use