Add the reliability where it matters most

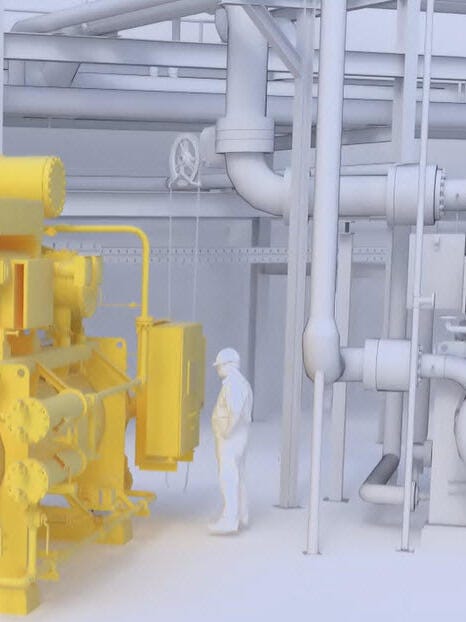

Vilter technology and industry expertise delivers the uptime and dependability needed in demanding Renewable Natural Gas (RNG) applications. More than 145 operating plants in North America rely on Vilter by Copeland single screw compression technology for consistent and quality production.

Make it easy. There is variability with gas quality specifications, utility negotiations, feed stocks, local and federal incentives, and various entities involved in a project. Vilter by Copeland innovation and expertise can help you navigate the options including:

- Blower skids to boost the initial biogas to maintain pressure across contaminant removal and optimize inlet pressure to the feed gas compressor

- Low-pressure and high-pressure chilling skids to dehydrate the biogas upstream and downstream of the feed gas compressor

- Single-screw feed gas compressor technology to pressurize the biogas upstream of the Carbon Dioxide removal technology

- Single-screw recycle and vacuum compressors or feed gas compressor for Nitrogen removal depending on the technology selected

- Single-screw product gas compressor technology to boost the biomethane to pipeline pressure including the unique Vilter High Pressure Low Displacement compressor model

- Fuel gas booster to provide pressurized biogas to a gas turbine for combined heat and power (CHP) technology.

Industry Leading Single Screw Technology

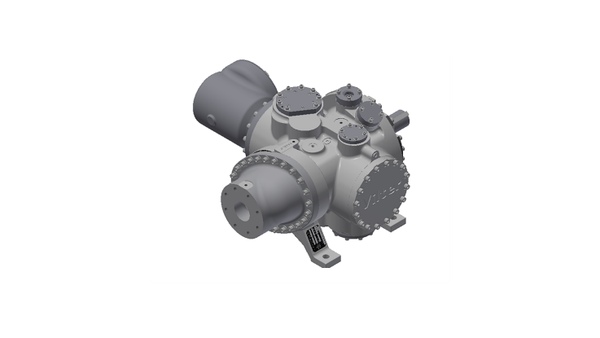

Our transformational solutions are powered by the efficient Vilter single-screw compressor, which enables industry leading up-time proven over decades of operation.

- Balance of axial and radial loading extends bearing lifespan for improved durability

- Precision mechanical modulation of capacity and pressure ratio through Parallex Slides enhances operational flexibility

- Simplified servicing ensures hassle-free maintenance

- Proven resilience in the most challenging environments, ensuring reliable performance

- Extensive 17-year track record of operating in the RNG space more than 145 facilities in North America all using single-screw compressors from Vilter by Copeland

- Single screw technology developed and fabricated in Wisconsin

Single Screw Compressors Deliver Scalability Across Balance of Plant

Vilter single screw compressors use a rotary, positive displacement compressor design to provide the lowest lifecycle costs and highest reliability of all gas compressors. A balanced design provides quiet and reliable operation, even while performing at pressures over 1,100 PSI.

Documents

| Name | Language | File Type | Link |

|---|---|---|---|

| Maintenance Poster | English | Download |

| Name | Language | File Type | Link |

|---|---|---|---|

| Maintenance Poster | English | Download |