State and International Regulations Continue to Drive HFC Refrigerant Phase-Down

The regulation of refrigerants continues to be a source of great uncertainty in the commercial refrigeration industry. At the heart of this issue is the subject of carbon emissions from hydrofluorocarbon (HFC) refrigerants and their potential contribution to climate change. As global, national and state regulations have targeted the phase-down of HFCs in recent years, the industry has seen a shift toward alternative refrigerants with lower global warming potential (GWP). While more environmentally friendly, these emerging options pose additional questions about performance and safety, with many of the lowest-GWP alternatives bearing a degree of flammability.

Refrigerant Lifecycle Performance

As we begin to transition away from hydrofluorocarbon (HFC) refrigerants, we also need to determine the sustainability impacts of these decisions. Our online lifecycle climate performance (LCCP) calculator allows you to input key data about current and proposed systems, compare performance, and devise a phasedown strategy that aligns with operational objectives.

Environmental Protection Agency (EPA)

In response to the 2017 court ruling, the EPA has also rolled back other HFC-related regulations. In particular, it excludes HFCs from the leak repair and maintenance requirements for stationary refrigeration equipment, otherwise known as Section 608 of the CAA.

The updated rule, which had been in effect since 2016, lowered the leak rate threshold in supermarket refrigeration systems from 35 percent to 20 percent and set forth specific requirements pertaining to HFC management. With the rescinding of this rule, refrigeration equipment with 50 pounds or more of HFC refrigerant would no longer be subject to these requirements.

Even if the leak repair and maintenance requirements of Section 608 are no longer enforced for HFC systems, an effective leak repair and maintenance program is still generally recognized as an industry best practice. Other beneficial provisions of Section 608 — including the certified technician program and the refrigerant recovery and reclamation rules — are still in effect.

California Air Resources Board (CARB)

In absence of regulatory certainty at the federal level, many states are adopting environmental regulations that seek to limit the negative impacts of short-lived climate pollutants (SLCPs) such as HFCs. California was the first state to take official action. California Senate Bill 1383, also known as the Super Pollutant Reduction Act, was passed in 2016 and requires that Californians reduce F-gas emissions by 40 percent by 2030. The California Air Resources Board (CARB) has been tasked with meeting these reductions.

Since 2016, CARB had been using EPA SNAP Rules 20 and 21 as the bases of its HFC phase-down initiatives. With the vacating of SNAP Rule 20 in 2017, CARB moved to adopt its compliance dates that were already implemented or upcoming. This first phase of CARB rulemaking took place in March 2018 and helped to maintain the progress that the state had already made in transitioning from HFC refrigerants.

To strengthen these efforts, California Senate Bill 1013 was signed into law in Sept. 2018. Referred to as the California Cooling Act, this law mandates the full adoption of SNAP Rules 20 and 21 as they read on January 3, 2017. Currently in effect, this law authorizes CARB to uphold future compliance dates and includes the following provisions:

- The option to modify compliance dates

- The ability to list or delist refrigerants, regardless of federal status

- Prohibits selling, leasing or renting equipment inconsistent with provisions

- Establishes an incentive program to promote the adoption of new refrigerant technologies

To reach the 40 percent reductions required by 2030, CARB also proposed an aggressive second phase of rulemaking that will further impact commercial refrigeration and AC applications. On December 10, 2020, the CARB board voted to approve the proposal, which includes the following requirements.

- Refrigerants with a GWP greater than or equal to 150 will not be allowed in new stationary refrigeration systems charged with more than 50 pounds, effective in 2022.

- Existing food retail facilities with refrigeration systems charged with more than 50 pounds must collectively meet a 1,400 weighted average GWP or 55 percent greenhouse gas potential (GHGp) reduction relative to a 2019 baseline by 2030.

- Refrigerants with a GWP greater than or equal to 750 will not be allowed in new stationary air conditioning equipment, effective 2023.

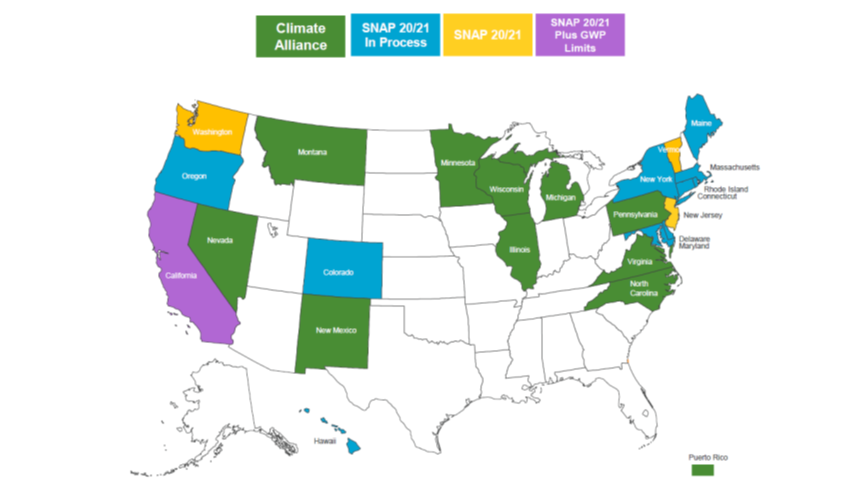

Other states follow California’s lead

With California taking a leadership role on environmental regulations, it’s very likely that other states will adopt a similar (if not identical) approach. In 2017, a coalition of 16 states and Puerto Rico emerged to form the U.S. Climate Alliance, with a shared commitment of reducing SLCPs and HFCs. Since then, the Alliance has grown to 25 members — comprising more than 55 percent of the U.S. population and an $11.7 trillion economy; several of its states have announced plans to follow California’s lead on HFC phase-downs.

Industry advocates, including the Air-conditioning Heating and Refrigeration Institute (AHRI) and the NRDC, have asked for states to be consistent in their approach to adopting CARB’s rules.

Refrigerant Safety Standards & Codes

Meeting the targeted emissions reductions in California will likely require the use of low-GWP refrigerants. But many of these low-GWP, hyrdrofluoroolefin (HFO) refrigerants are classified as A2L, or mildly flammable. The natural A3 refrigerant R-290 (propane) is also becoming more widely used in low-charge, self-contained commercial refrigeration applications. Currently, national and global governing agencies are evaluating the standards that establish allowable charge limits and the safe use of these A2L and A3 refrigerants.

Per a 2019 update from the International Electrotechnical Commission (IEC) to IEC60335-2-89, A2L and A3 charge limits have been increased for commercial refrigeration systems as follows:

- A2Ls — from 150g to 1.2kg

- A3s — 500g for factory-sealed systems, and will remain at 150g for split systems

While the U.S. doesn’t rely on the IEC to establish its safety standards, similar efforts to raise A2L and A3 charge limits are also taking place here. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and Underwriters Laboratory (UL) are working to establish new charge limits and mitigations for the use of A2L and A3 refrigerants with support from industry and various stakeholders.

Once adopted, these standards will serve as the bases for codes that govern building, fire and other local authorities having jurisdiction (AHJ), who will ultimately oversee the applications in which these refrigerants are used. It’s important to remember that building codes vary from state to state; thus, the adoption of flammable refrigerants ultimately will take place on local levels and may take years to accomplish.

The Kigali Amendment to the Montreal Protocol

Among the regulatory uncertainty in the U.S., it’s easy to forget that the Montreal Protocol has been evaluating the global warming potential of HFCs for nearly a decade. In 2016, 197 countries met in Kigali, Rwanda, and agreed on a global proposal to phase down HFCs. The Kigali Amendment requires ratification from at least 20 countries to take effect; 92 countries (including the E.U., but not including the U.S.) have since ratified it. As such, it took effect for participating countries on January 1, 2019.

While the U.S. is considering ratification, many industry stakeholders believe it would be beneficial to our current state of regulatory and economic affairs. Ratification could help to establish a framework for future refrigerant regulations that would provide the certainty needed to help the industry and regulatory bodies alike move forward with a unified approach.

According to an economic study co-sponsored by AHRI and the Alliance for Responsible Atmospheric Policy, ratifying the amendment could create up to 33,000 jobs in the manufacturing sector by 2027 and is expected to have a positive impact on the U.S. economy. For these reasons, many in the industry are in favor of ratification and have demonstrated this through letters of support to the Senate and the White House.

Department of Energy (DOE)

Refrigerants are only one factor in the regulatory equation affecting HVACR industry; it is also dealing with energy mandates by the DOE. While these were introduced in 2014, they have evolved to present significant implications across three classes of commercial refrigeration equipment.

Commercial Refrigeration Equipment (CRE). Since the enforcement date of March 2017, new CRE have been subject to 20-86% energy reductions, depending on the specific class of equipment. Compliance equations are factored according to the unit’s daily energy consumption (kWh/24-hour) and its total display area.

Automatic Commercial Ice Makers (ACIM). As of January 2018, new ACIMs must achieve 5-25% energy reductions, as measured in kWh/100 lb. of ice. Again, each equipment class has a specific equation to measure compliance, so OEMs must be certain of their particular class requirements.

Walk-in Coolers and Freezers (WICF). WICF manufacturers are looking at a 2020 enforcement date to reduce energy consumption by 30-37%. These reductions are measured according to the AHRI-1250 annual walk-in efficiency factor (AWEF) standard. It is worth noting that while the original benchmark set for this standard has been reduced through persistent industry negotiations, it still represents a significant energy reduction target for WICF equipment.

Complying with DOE Standards on Walk-In Coolers and Freezers

As of January 1, 2020, original equipment manufacturers (OEMs) are expected to manufacture WICFs that meet the DOE’s minimum AWEF standards. The DOE’s WICF ruling has broad impacts to the industry, from OEMs and wholesalers to contractors and end users.

We’ve developed materials to help guide you through the compliance transition process. If you have additional questions, download these resources or contact your sales representative.