Copeland Scroll Two-Stage Compressors

The Copeland scroll two-stage compressor is ideal for high SEER performance and provides an easy-to-apply solution to enhance system efficiency for both air conditioners and heat pumps.

Improved Humidity and Temperature Control

Systems using Copeland scroll two-stage compressors normally operate at 65 percent of full capacity, allowing longer cycles that reduce relative humidity and temperature fluctuations. As outdoor temperatures rise and demand for cooling increases, the thermostat will detect and signal the compressor to shift to 100 percent capacity until the interior temperature set point is reached.

How does a Copeland scroll two-stage compressor work?

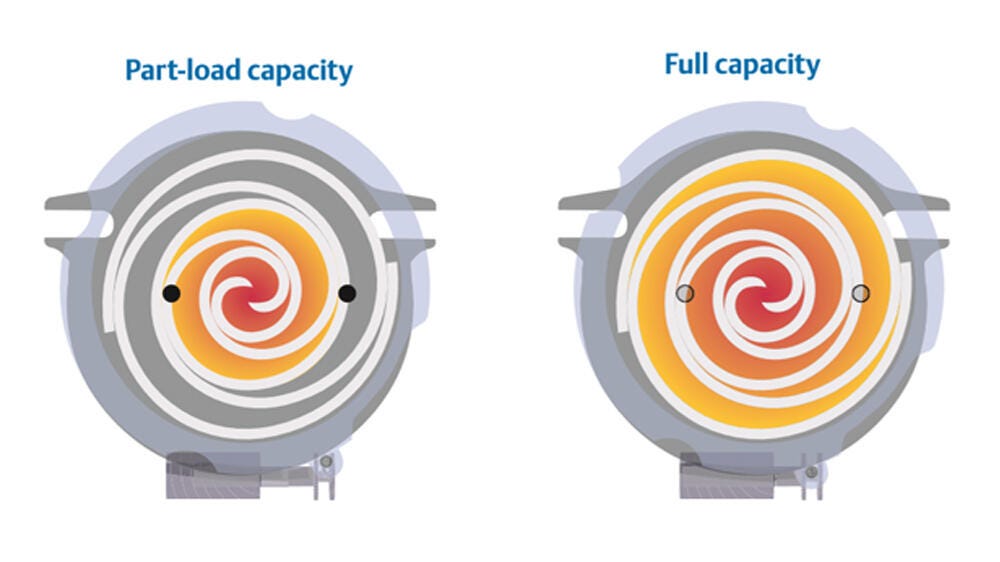

Two-stage modulation adjusts compressor capacity by bypassing a portion of the gas in the scroll back to suction. By doing so, the compressor can closely match the heating or cooling demand allowing it to cycle less frequently.

It uses internal pressure to actuate the modulation scheme, requiring only a low voltage signal from the thermostat to the controlling solenoid valve on the compressor. When actuated, output shifts from 65 percent (part-load) to 100 percent (full load) capacity to adjust for increased load requirements.

Watch the video to learn more.

HVAC on Air Podcast

In this episode, Local contractors along with co-hosts, Lindsay Headings and Vickie Blakey, are joined by three Logan Services HVAC customer service experts to discuss their strategy selling Trane 16-18 SEER two-stage systems. These industry experts provide insight on the benefits of talking through two-stage technology with the homeowner, affordable comfort, reliability, and other topics.

Stay up-to-date with the latest news on Copeland™ scroll! Follow us on LinkedIn.